The electric scooter revolution has taken the world by storm, reshaping how people commute in cities and suburbs alike. With their sleek designs, portability, and zero-emission benefits, e-scooters have quickly become a symbol of sustainable mobility. They offer an eco-friendly alternative to cars and motorcycles, reducing traffic congestion and air pollution while providing an affordable solution for short-distance travel. For many urban dwellers, electric scooters are more than just a means of transport they represent a lifestyle shift toward smarter, greener, and more flexible living.

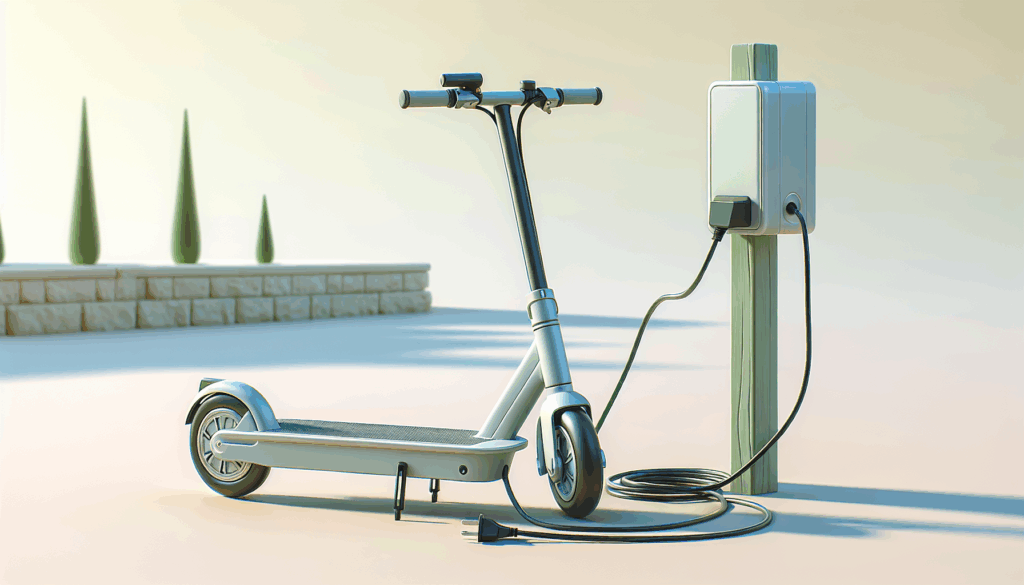

Yet, as exciting as this revolution is, one major concern continues to surface: the cost of electric scooter batteries. While these vehicles are marketed as cost-effective, the reality is that their most important component the battery often accounts for a significant portion of the overall price. Riders are increasingly asking why electric scooter battery remain so expensive and whether it’s possible to find affordable options without compromising on quality, safety, or performance. This question is central to the long-term growth of the industry and the accessibility of e-scooters for everyday users.

Understanding the true cost of electric scooter battery requires looking deeper into their design, technology, and production challenges. From the materials used such as lithium, cobalt, and nickel to the advanced safety and performance features built into modern battery systems, several factors drive up expenses. Add to that the rising global demand and stricter environmental regulations, and the picture becomes clearer. By unpacking these elements, we can uncover the mystery behind battery pricing and see where the future of e-scooter affordability might be headed.

The Anatomy of an Electric Scooter Battery

A high-quality electric scooter battery is far more than just a simple energy pack it is a carefully engineered system designed to deliver consistent performance, reliability, and safety. At its core are lithium-ion cells, which store and release the energy needed to power the scooter. Surrounding these cells are electronic control units (ECUs) that regulate current flow, prevent overcharging, and protect against short circuits. In addition, thermal management systems ensure that the battery maintains an optimal temperature during charging and discharging, preventing overheating and prolonging its lifespan. Finally, protective casings provide structural integrity and shield the internal components from physical shocks, moisture, and dust.

Each of these elements adds complexity and precision to the design process, and naturally, this complexity drives up the cost. Unlike low-quality alternatives that may cut corners in safety or durability, premium batteries must undergo rigorous engineering to guarantee long-term reliability. For manufacturers, investing in advanced battery design means higher production costs, but for consumers, it translates into better performance, longer range, and peace of mind when riding.

The price of an electric scooter battery is also heavily influenced by the raw materials used in production. Lithium, cobalt, and nickel key ingredients in lithium-ion chemistry are expensive and subject to global market fluctuations. As demand for these materials grows, not only from the electric scooter industry but also from electric cars and renewable energy storage, their prices continue to rise. This dependency on scarce and costly resources significantly contributes to the final retail price of every high-quality electric scooter battery.

The Impact of Manufacturing Processes

Another significant factor influencing the cost of electric scooter battery is the manufacturing process itself. Unlike simpler consumer electronics, battery production involves a series of highly technical and resource-intensive steps. High-volume production lines rely on advanced robotics and precision equipment to ensure accuracy at every stage of assembly. Even small errors in cell alignment, welding, or sealing can compromise safety and performance, which is why manufacturers invest in state-of-the-art technology and highly skilled labor. These investments inevitably increase production costs, which are then reflected in the final retail price of the battery.

Equally important are the rigorous quality control measures implemented during the manufacturing process. Each battery must undergo extensive testing for capacity, durability, and safety before it reaches consumers. This includes stress testing, cycle testing, and performance monitoring under different operating conditions. Such procedures are not optional but necessary to ensure compliance with international safety standards and to prevent risks such as overheating, leakage, or fire hazards. While these steps add to production expenses, they also guarantee reliability and customer trust in the product.

Companies like Eko Life Malaysia go a step further by investing heavily in research and development alongside manufacturing. This R&D focus allows them to experiment with new battery chemistries, smarter thermal management systems, and safer protective designs. Although these innovations enhance the overall performance and longevity of the batteries, they also require significant upfront spending, which translates into a higher price tag. Ultimately, the meticulous manufacturing process ensures that consumers receive a premium, dependable product but at a cost that reflects the complexity and precision behind it.

The Role of Research and Development

Research and development (R&D) plays a crucial role in shaping the future of electric scooter battery. Unlike basic manufacturing, which focuses on mass production, R&D is about exploring new chemistries, materials, and designs that can significantly enhance performance. Companies like Eko Life Malaysia invest heavily in developing batteries with higher energy density, faster charging capabilities, and improved safety features. These advancements directly translate into a better riding experience, giving users longer ranges, smoother power delivery, and greater reliability on the road.

However, innovation does not come cheap. The process of testing new technologies, refining prototypes, and conducting safety trials requires significant financial and technical resources. For example, experimenting with solid-state batteries or advanced thermal management systems can take years of research before reaching market readiness. Each breakthrough involves both successes and failures, and the costs of these developmental stages are eventually passed down to consumers in the form of higher prices. While some may view this as a drawback, it is the price of progress and a necessary step toward building safer and more sustainable e-mobility solutions.

From a consumer perspective, these R&D investments bring long-term benefits. A battery designed with advanced technology not only lasts longer but also reduces the need for frequent replacements, lowering overall lifetime costs. Furthermore, innovation ensures compliance with evolving global safety and environmental regulations, giving riders peace of mind. While the upfront cost of an electric scooter battery may be higher due to R&D expenses, the value delivered over time justifies the investment. In this way, research is not just an expense it is an essential driver of quality, safety, and sustainability in the e-scooter industry.

Quality Control Measures

Quality control measures are another critical factor that directly influences the price of electric scooter batteries. Because batteries are the heart of every e-scooter, ensuring their safety and durability is non-negotiable. Manufacturers such as Eko Life Malaysia implement strict testing protocols to guarantee that each battery can withstand real-world conditions. These include thermal stress tests, vibration resistance, charge–discharge cycle analysis, and short-circuit prevention checks. Such rigorous processes are essential to protect consumers from hazards like overheating, swelling, or even fire risks that are sometimes seen with poorly manufactured, low-cost alternatives.

Implementing these quality control measures, however, significantly increases production costs. Every additional test requires specialized equipment, trained technicians, and longer production times. Batteries that fail to meet standards are discarded or recycled, which further adds to expenses. For premium manufacturers, this meticulous approach ensures that only safe, reliable products reach the market. In contrast, cheaper models that cut corners on testing may come with a lower price tag, but they often compromise long-term performance and user safety.

From the consumer’s perspective, paying slightly more for a battery that has undergone rigorous testing is an investment in peace of mind. Reliable quality control not only reduces the likelihood of sudden battery failures but also extends the lifespan of the scooter, making ownership more cost-effective in the long run. Ultimately, the emphasis on quality control guarantees that riders enjoy a consistent, safe, and dependable experience though it does contribute to the overall cost of electric scooter battery.

Certifications and Compliance

Compliance with international regulations and certifications is another major factor shaping the cost of an electric scooter battery. Because batteries are the most critical and sensitive component of an e-scooter, they must meet stringent global safety requirements before being sold to consumers. Certifications such as CE (Conformité Européenne), UL (Underwriters Laboratories), and TUV (Technischer Überwachungsverein) are designed to ensure that every electric scooter battery meets strict performance, safety, and environmental standards. Achieving these certifications requires extensive testing, documentation, and third-party audits all of which add layers of expense for manufacturers.

For companies like Eko Life Malaysia, obtaining these certifications is not optional but essential. By certifying each electric scooter battery, they can guarantee that their products are safe, reliable, and globally compliant. This process involves testing the battery’s thermal stability, electrical performance, resistance to overcharging, and ability to withstand real-world operating conditions. While these requirements increase production costs, they also protect riders from the risks associated with low-quality, uncertified batteries. For consumers, this assurance is a key reason why certified electric scooter batteries are often priced higher.

In the bigger picture, regulatory compliance adds credibility to the industry. As electric scooters become more widely adopted worldwide, governments and international bodies are enforcing stricter safety rules. Manufacturers that invest in compliance are not just raising the price of an electric scooter battery they are building consumer trust and ensuring long-term sustainability. Although it increases costs, certification ensures that riders enjoy both safety and performance, making it a worthwhile investment for the future of e-mobility.

The Future of Electric Scooter Batteries

As the electric scooter industry continues to evolve, the future of the electric scooter battery looks promising. With demand rising worldwide, manufacturers and researchers are under constant pressure to develop solutions that balance performance, safety, and affordability. Current trends suggest that innovations in battery chemistry such as solid-state batteries, graphene-enhanced cells, and improved lithium-ion formulations could significantly increase energy density while reducing costs over time. These breakthroughs will allow electric scooters to travel longer distances, charge faster, and deliver better reliability, all at a lower cost per unit.

Manufacturers like Eko Life Malaysia are expected to play a key role in shaping this next chapter. By investing in sustainable design practices and modular battery systems, they aim to make replacement and recycling easier for consumers. Such advancements not only reduce waste but also address growing concerns about the environmental impact of large-scale battery production. As sustainability becomes a global priority, companies that can produce eco-friendly, long-lasting electric scooter batteries will gain a competitive edge.

Looking ahead, the combination of innovation, sustainability, and mass production is likely to make electric scooter ownership more accessible than ever. While prices are high today, the trajectory points toward affordable, high-performance solutions that align with eco-conscious lifestyles. In the near future, the electric scooter battery will no longer be seen as the most expensive barrier to entry, but rather as a symbol of progress powering greener cities and more sustainable transportation worldwide

Conclusion: Unlocking the Secrets of Electric Scooter Batteries

In conclusion, understanding why an electric scooter battery can be so expensive requires looking at the bigger picture. Every element from the lithium-ion cells and thermal management systems to the advanced electronics and protective casings adds both complexity and cost. When combined with the challenges of sourcing raw materials, manufacturers are left with little choice but to pass some of these expenses onto consumers. The result is that electric scooter batteries often represent the single most costly component of the entire vehicle.

Beyond components, factors such as manufacturing precision, research and development, quality control testing, and global certifications all contribute to the final price tag. These processes ensure that every electric scooter battery on the market is safe, durable, and compliant with international standards. While these measures inevitably drive-up costs, they also guarantee performance and peace of mind for riders. In the long run, investing in a well-built battery is not just about affordability it’s about safety, reliability, and long-term value.

As enthusiasts, we see this not as a drawback but as an opportunity for innovation. Companies like Eko Life Malaysia continue to push the industry forward by delivering high-quality, certified, and reliable products that balance cost with performance. Whether you are an experienced rider or new to the e-scooter lifestyle, it’s important to understand the factors shaping electric scooter battery prices. With ongoing advancements in technology, the future promises more affordable, efficient, and sustainable solutions that will keep powering the global e-mobility revolution.